Our laser cutting and plans will continue. As accessory items sell out they will not be restocked

Airborne Plans have new owners. Gus McKendrick and Peter Barry. Email them for all your plan requirements. gus@airbornemodels.com.au

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

- Quick View

- Add to WishlistAdd to Wishlist

- Read more

- Quick View

- Add to WishlistAdd to Wishlist

- Read more

- Quick View

- Add to WishlistAdd to Wishlist

- Read more

- Quick View

- Add to WishlistAdd to Wishlist

- Select options

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

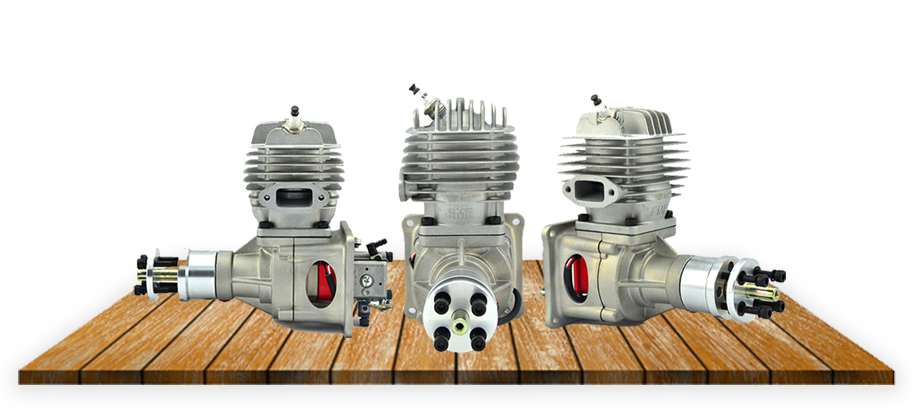

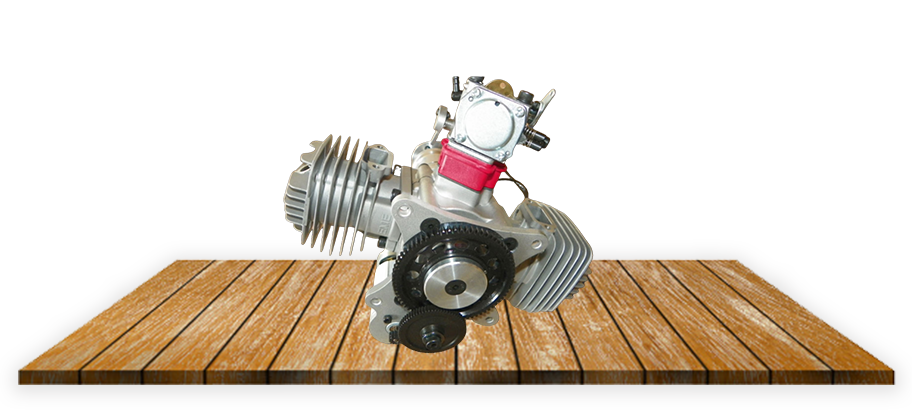

DLE Engines

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

New Arrivals

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

- Quick View

- Add to WishlistAdd to Wishlist

- Add to cart

Safe Handling

Sanitized Warehouse